Alfieri's plan was a simple but effective one and was influenced by the need to make production as economical as possible whilst ensuring quality and reliability. To achieve this Alfieri modified the competition 6-cyl engine from the 350S for road use and incorporated some major components from leading manufactures in Europe: a ZF (Zahnradfabrik of Friedrichshafen) gearbox, a Borg and Beck clutch, a Salisbury rear differential and front and rear suspension parts from Alford Alder. The 3500GT was first presented at the Geneva Motor Show in March 1957. Two prototypes were displayed on the Maserati stand: one by Allemano, the then traditional designer for the 'Casa del Tridente' and the other the work of Carrozzeria Touring of Milan. Touring had designed a very elegant 2+2 coupé and Omer Orsi chose this design for the series production.

The 3500GT's twin overhead camshaft six cylinder engine fed by three twin choke 42 DCOE Weber carburettors had a cubic capacity of 3,485 with a compression ratio of 8.5 to 1 developing some 220 bhp at 5,500 rpm. The chassis frame was a multi-tubular structure of high-duty steel giving the car a total dry weight of 1300 kg. Braking was by hydraulically operated 12-inch drum brakes. The front suspension was by coil-springs and wishbones with a torsion anti-roll bar and rear suspension by semi-elliptical leaf-springs with a live rear axle.

Between late 1957 and early 1958 the 3500GT entered production. The production 3500GTs differed slightly from the prototype with alterations to the headlamps and indicators, a re-designed radiator grille, minor alterations to the dashboard and other smaller details. The 3500GT remained unchanged until early 1965 when numerous modifications were made many of which were optional. In 1959 optional front disc brakes were available (standard equipment in 1960), a limited slip differential (standard equipment in 1960) and Borrani knock-on wire wheels.

In 1958 after having captured the Formula 1 World Championship and, but for some bad luck, almost capturing the World Sportscar Championship Maserati entered some dark days financially.

Omer Orsi had given Giulio Alfieri the task of designing a fast reliable road going sports car that could be produced in larger numbers. Maserati had until then produced competition cars in very low numbers mainly in response to orders from individual customers. It was this strategy that was to change Maserati's fortunes.

Alfieri's plan was a simple but effective one and was influenced by the need to make production as economical as possible whilst ensuring quality and reliability. To achieve this Alfieri modified the competition 6-cyl engine from the 350S for road use and incorporated some major components from leading manufactures in Europe: a ZF (Zahnradfabrik of Friedrichshafen) gearbox, a Borg and Beck clutch, a Salisbury rear differential and front and rear suspension parts from Alford Alder.

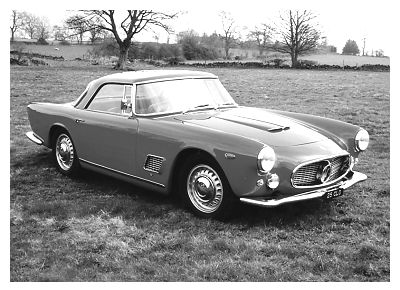

The 3500GT was first presented at the Geneva Motor Show in March 1957. Two prototypes were displayed on the Maserati stand: one by Allemano, the then traditional designer for the 'Casa del Tridente' and the other the work of Carrozzeria Touring of Milan. Touring had designed a very elegant 2+2 coupé and Omer Orsi chose this design for the series production.

The 3500GT's twin overhead camshaft six cylinder engine fed by three twin choke 42 DCOE Weber carburettors had a cubic capacity of 3,485 with a compression ratio of 8.5 to 1 developing some 220 bhp at 5,500 rpm. The chassis frame was a multi-tubular structure of high-duty steel giving the car a total dry weight of 1300 kg. Braking was by hydraulically operated 12-inch drum brakes. The front suspension was by coil-springs and wishbones with a torsion anti-roll bar and rear suspension by semi-elliptical leaf-springs with a live rear axle.

Between late 1957 and early 1958 the 3500GT entered production. The production 3500GTs differed slightly from the prototype with alterations to the headlamps and indicators, a re-designed radiator grille, minor alterations to the dashboard and other smaller details. The 3500GT remained unchanged until early 1965 when numerous modifications were made many of which were optional. In 1959 optional front disc brakes were available (standard equipment in 1960), a limited slip differential (standard equipment in 1960) and Borrani knock-on wire wheels.

In 1961 a five-speed ZF gearbox was fitted as standard but the major change was the introduction of the 3500GTI fitted with a Lucas direct fuel injection system with power increased to 235bhp. In 1962 with the 3500GT beginning to look dated some alterations were made to improve its looks with the removal of the side and bonnet air vents.

In 1960, Carrozziera Vignale introduced a 3500 spider on a shortened chassis, a design strongly influenced by the Coupé of Touring.

The 3500GT was more entitled to be named a 'sports car' than a 'gran turismo'. Powered by an engine evolved from the 250F and based on the successful 350S sports racer, the 3500GT had a maximum speed of around 145 mph and excellent acceleration.

However when it came to appearances, there was nothing sports racer about this car with its elegant coachwork and an interior that oozed luxury.

The 3500GT is important in that it was Maserati's first production car to be built in substantial numbers with 1972 cars built over a period of nine years. During this period Frua, Bertone, Zagato and Michelotti designed bodies on the 3500's chassis but none possessed the classic lines of the Touring design. |